DOUBLE COLUMN MACHINING CENTER

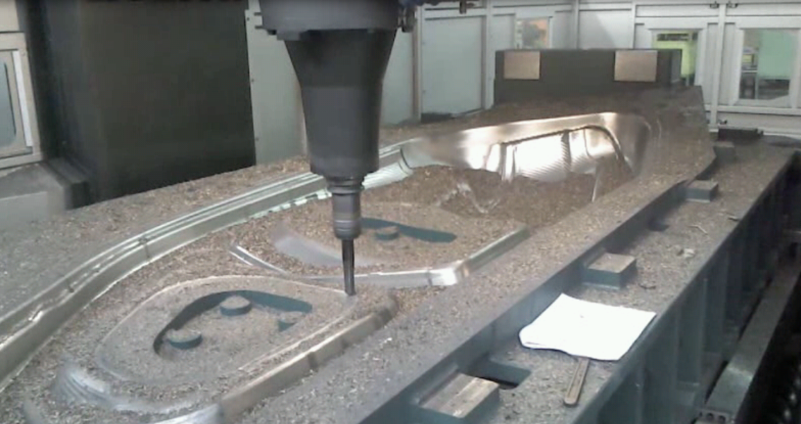

Double Column Machining Centers in multiple Axis sizes, Spindles, Attachments and Controllers; provide versatile configurations for Die Mould, Heavy and Large Part machining with minimum number of setups and high quality results.

Large Parts

90 Deg Head

Mould Machining